It’s time to build a beehive for my soon-to-arrive package bees. If you’ll soon be starting beekeeping, you can build your hive right along with me, step by step.

You’ll see that building a honeybee hive from a beehive kit is really easy. If I can do it, anyone can!

And I can do it.

Here’s my hive all set-up and with bees just installed; the very same hive shown built on this page:

‘Course, I’ve had lots of practice through the years. But I still remember: building that very first kit certainly involved some head-scratching.

So for your first kit, just follow the instructions below. Eliminate the head-scratching.

Before We Get Started…

Do you have your hive kit yet? If you do, then you’re ready to follow along step-by-step as we build it.

Best Beehive Start Kits

Best Beehive Start Kits

And if not? Here are my top two beehive start kits:

- MayBee Beehive Starter Kit (Including beekeeping tools)

- Hoover Hives Langstroth Starter Kit (including some tools)

Best Beehive Kit

- Hoover Hives 10 Frame Langstroth Bee Hive Kit (100% beeswax coated

- BeeCastle Complete Beehive Kit (100% beeswax coated)

- Honey Keeper Beehive 20 Frame Kit

Don’t Procrastinate!

Don’t procrastinate like I did! It’s March 28, my bees are due in a couple of weeks, and I’m just now getting around to building a bee hive. It would be best to start a bit earlier, just to be sure that everything is ready on time.

It doesn’t take two weeks to build a bee hive, of course. In fact, I did everything except paint the hive in one afternoon. But if it turns out that you’re missing something, or accidentally ruin a piece and have to reorder, you don’t want to cut it too close.

You Don’t Want Bees Arriving Before You’re Ready!

And as it turns out, I almost put myself in that very situation!

I thought that I had everything on hand needed to build a bee hive. Turns out, though, that I was 3 sheets short of having enough foundation. I’ll have to order some. I expect it will arrive in time, but I’m cutting it plenty close.

So if you’re a chronic procrastinator like me, try not to be – at least when it comes to your beekeeping!

Got Your Kit? OK, Let’s Get to Building…

And it’s a common complaint that hive kits generally come with instructions that aren’t terribly helpful (a few reviewers made that complaint about the kits I recommended above).

But the tips and photos below will help to make building your first hive easy. I bet you’ll even have fun doing it!

Note: This page consists of photos illustrating the process of building a standard Langstroth bee hive – by far, the most popular type of hive. So if you haven’t already, you might want to take a quick look at this page: the parts of a beehive, for a part-by-part description of a Langstroth hive.

By the way, I’ll let you know at each step what size nails to use – a common point of confusion for newbies. But if you build a bee hive from a kit, it’s unlikely you’ll have to buy any nails since they usually are included.

So let’s get started.

Let’s just begin at the bottom of the hive, and work our way up. Or if you’d like to jump to a specific hive component, just click the appropriate link:

The Bottom Board

I use wood glue when assembling all hive components. Here you see a bead of glue laid in the groove of the bottom board’s tongue-and-groove construction.

Tap all the pieces firmly together, apply glue to the side rails, and fit board assembly into the side rails.

Making sure that the boards are flush with the end of the rail, place 1 nail (2 ¼” galvanized) toward the end of the side rail.

Now make sure that the boards are nested together tightly, with no gaps in between the pieces, and place 1 nail toward the other end of the side rail.

(CAUTION: Note that the groove cut in the side rails is not centered. When adding the side rails, be sure that they are not mismatched, with the deep side up on one side, and the shallow side up on the other side.)

This type of bottom board is called a ‘reversible bottom board.’ The purpose of the reversible bottom board is to have a deeper entrance in the summertime, with the ability to flip the board and have a shallower entrance in winter without having to change bottom boards.

I always use the deep side all year round, and never bother to reverse it for winter. But I still add the shallow end cleat for extra structural rigidity.)

Repeat these steps with the other side rail. You’ll then have a nail in each corner, holding the entire assembly tightly together. You can then add a few more nails in between the corner nails on each side rail.

Now nail and glue on the top and bottom cleats. They go on opposite ends.

It will be obvious which side each goes on because they match the height of the side rails. (Top cleat uses 1 ½” nails, and 1” on the bottom.)

Sometimes parts won’t fit exactly right, and you’ll have to do a bit of trimming. As you can see, that was the case for the bottom cleat, which I had to trim to fit.

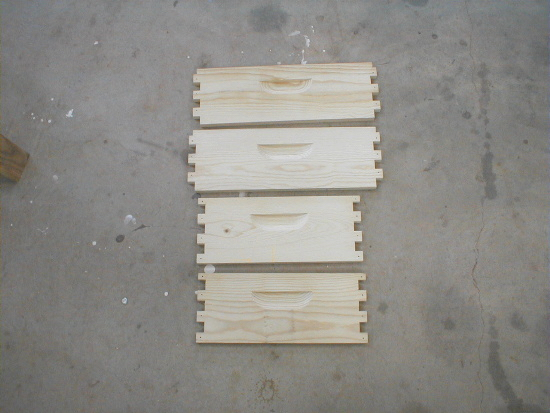

The Hive Body

I use medium depth supers exclusively (except for comb honey supers). I like having all pieces of equipment being interchangeable.

And the older I get, the less interested I am in having to lift a deep hive body full of honey!

So I’ll be starting my hive with 2 medium hive bodies rather than 1 deep.

First, I apply glue to all of the box joints.

Assemble the pieces, and drive 1 nail (2 ¼” galvanized) in each bottom corner, front and back.

Making sure that the assembly stays square, drive another nail in each corner front and back. These nails should go one hole down from the top (the top uses a smaller nail).

I then drive nails in all the remaining pre-drilled holes. The top front/back nails are 1 ½” galvanized.

Frames

I use grooved top bar frames because they work great with my favorite foundation, Plasticell.

I start out by applying a dab of glue to each end of the top and bottom bars.

Then assemble the frame, and drive 2 nails (1 ¼”) into the end bar at each corner.

It will certainly do no harm to use a carpenter’s square to check that the frame is true, but I usually just eyeball it.

If you’re building a deep frame, though, you’ll probably want to use a square (or a frame jig). With medium and shallow depth frames, it’s pretty unlikely that the frame will end up badly out of square.

Now comes the only part that’s a bit tricky – cross nailing. It’s worth the extra time and trouble, though.

And if you don’t do it, you may really wish you had one day when the top bar pulls off the frame as you’re trying to pry it up from the hive.

To cross nail, you’ll just drive a nail through the end bar into the top bar, one on each end.

It’ll take a bit of trial and error to get the angle just right.

If the angle is too slight, the nail will end up in the foundation groove. Too great an angle, and the nail will protrude from the top bar.

The approximate angle is shown in the photo.

Adding Foundation

I use Plasticell foundation, which makes inserting foundation a snap – literally.

I just insert one end of the foundation into the bottom bar groove, and lay the frame on a flat, firm surface. The top of the foundation will be resting on the side of the top bar.

Then just press firmly in the middle of the foundation (using both hands when one’s not occupied with a camera!), until the foundation bows enough for the top to snap into place in the top bar groove.

Couldn’t be easier!

Inner Cover

Apply glue, and insert the 2 side rails into one end cleat.

Slide the Masonite piece into the side rails and fit the other end cleat in place.

Drive 2 nails (3/4”) in each corner, then flip the cover over, and drive one additional nail in each corner.

Outer Cover

Building the outer cover is very similar to building the bottom board. Begin with applying a bead of glue in the groove of each piece.

Fit the tongue-and-groove pieces together, use a hammer to tap them snug, and then slip on the end rails.

Making sure that the boards are flush with the end of the rail, place 1 nail (1 3/8” galvanized) toward the end of the side rail.

Now make sure that the boards are nested together tightly, with no gaps in between the pieces, and place 1 nail toward the other end of the side rail.

Repeat these steps with the other side rail. You’ll then have a nail in each corner, holding the entire assembly tightly together.

You can then add a few more nails in between the corner nails on each side rail.

Now just glue and nail the top cleats in place.

A Little Paint, and the Hive Will be Ready

All that’s left to do now is paint. And that’s an important step.

I wouldn’t build a bee hive and put it into service without painting it first. It just won’t last nearly as long unpainted.

I’ll pick a nice day when I can take the hive components outside, and I’ll apply 2 coats of an exterior grade latex paint. Any color will work, but I prefer white for the

I’ll paint all surfaces of the bottom board and outer cover. I’ll paint only the exterior surface of the hive bodies. I won’t paint the inner cover at all.

And of course the frames won’t be painted, either.

You’ll Find it’s Easy to Build a Bee Hive…

Whew – it was almost more work to describe building the hive than it was to actually build it!

And it might seem to you that it takes a lot of work to build a bee hive, but it’s really not too bad.

Except for painting, I did all of the above in less than 4 hours – including the time spent taking photos for documenting the process.

I think you’ll find that it’s not only easy to build a bee hive, but also kind of fun. And there’s a nice sense of accomplishment in having your hive finished and ready, just waiting for your bees to arrive.

Did You Get Your Hive Built?

How did it go? Do you have any questions about the process? Anything you learned that might help other newbie beekeepers?

Please share! And if you have any photos of your new hive, we’d love to see them!